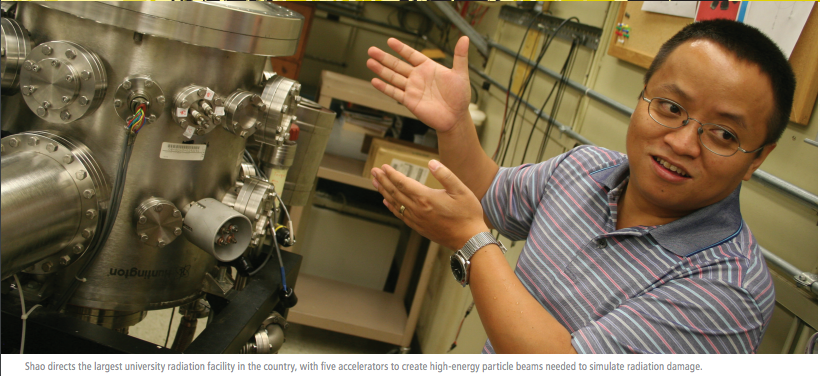

The University of Tennessee at Knoxville hosted an invited seminar and webinar given by Texas A&M Engineering Experiment Station (TEES) senior research scientist Dr. Frank Garner regarding work he and Dr. Lin Shao, associate professor in the Department of Nuclear Engineering at Texas A&M University, have produced on the study of material behaviors under extreme conditions. Garner is a member of Shao’s research group, which pioneers both accelerator-based irradiation testing and research directed at understanding the fundamentals of radiation materials science. Garner’s seminar covered how self-ion irradiation at accelerated rates simulates damage to reactor materials over time and creates void swelling within the reactor material. The research team hopes to identify stronger materials to use through these tests to ensure improved reactor structural safety.

According to Garner, nuclear power reactors have a large amount of structural steel. When the reactor is first brought to power, these structural systems are in optimum shape and all safety considerations needed to safely operate the reactor are accounted for in the design. However, there is a concern that over time, exposure to the radiation produced under the reactor’s operating conditions can effect the reactor’s structural integrity. Neutrons that bounce around during these nuclear reactions have the ability to transfer their energy into the atoms that make up this structural steel and, as a result, displace other atoms within the steel and cause the steel to become fragile.

“If I said 50 displacements per atom (DPA) occur, that means every atom in the steel, on the average, over it’s lifetime has been displaced 50 times,” said Garner. “It makes you wonder how the material remembers what it used to be.”

According to Garner, as a consequence of this displacement, the steel swells and grows, and can create a structural issue that Garner calls irradiation creep. Creep and swelling have been known to be life-limiting degradation issues for fast reactor structural materials and could be limiting for other reactor types. While research had been conducted about the effects of irradiation creep in the 1970s and 1980s, interest in the issue has recently resurged. With improvements in calculation and measurement tools, researchers have achieved a better understanding of the phenomenon.

“If swelling in these steels gets to be around 10 percent, certainly in an excess of 10 percent, the steel develops a brand new method of fragility and it becomes very fragile,” Garner said. “This is the major limitation of using these steels in the nuclear reactor because I cannot exceed 10 percent swelling because of a safety consideration.”

Garner’s solution to the issue of irradiation creep is to change the type of steel used structurally in reactors to prevent swelling. The project Garner and Shao have been working on has been studying different types of materials using accelerated ion-radiation to simulate irradiation creep and determine metals that may be resistant to its effects. The team is currently testing ferritic alloys they have determined would be better materials than the austenitic alloys used as structural materials in the past.

“In Texas we’re taking every ferritic -martensitic and ODS [oxide-dispersion-strengthened] variant of that alloy in the world and we’re routinely taking them all to 1,000 DPA,” Garner said. “We’re hunting for why is this one swelling later than that one, and we take that clue to make a better alloy, and that’s what the Texas program is about.”