About 350 million tons of dredged sediments are excavated annually in U.S. waters. Nearly all major ports in the world have at some time required dredging.

One of the most efficient and versatile types of modern dredges is the cutter suction dredge which uses a cutter located at the entrance to the suction pipe to excavate the sediment bed at the bottom of a ship channel. A centrifugal pump transports the excavated material consisting of gravel, sand, silt, clay and water to a desired placement location. Often, debris such as unexploded ordnances, roots, large rocks and logs enters or blocks the suction inlet causing safety concerns, delays or loss of production.

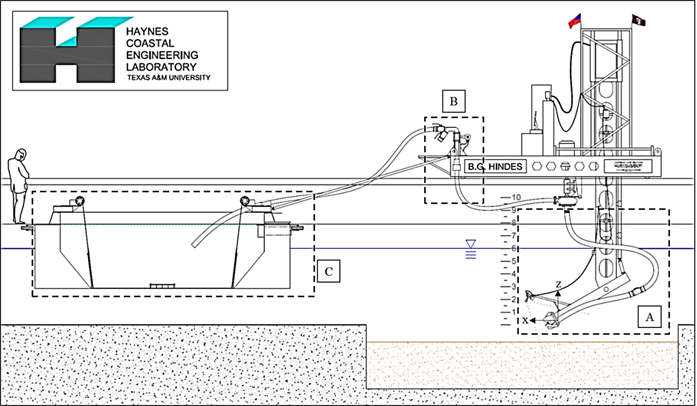

Dr. Robert Randall, W. H. Bauer Professor in Dredging Engineering in the Department of Ocean Engineering at Texas A&M University, conducted laboratory experiments using a model dredge at the Haynes Coastal Engineering Laboratory to research this problem. He studied the effectiveness of a steel screen attached to the suction entrance of a model cutter dredge to keep debris from entering the dredge pump system.

“If a pencil is caught in a vacuum cleaner, it will break up and possibly jam the machine,” said Randall. “Similarly, the cutter at the suction inlet of a dredge is meant to excavate sand. Debris such as unexploded ordnances can get caught inside the suction pipe or pump and could explode.”

The placement of screens over the suction mouth during dredging in certain areas suspected to have buried ordnance, per government regulations, is mandatory.

“Generally, the screens affect production,” said Randall. “We have to sacrifice production if the dredging operations are undertaken where hazardous ordnance are suspected to be present.”

An ideal screen would protect the dredge against debris and maximize production and reduce delays.

Randall experimented with various sizes and shapes of screen openings by creating a model dredging operation at the Haynes Coastal Engineering Laboratory. Randall’s model dredge was designed for up to a 1:10 scale model of a real dredge. The model dredge has a four inch suction pipe and three inch discharge pipe, and the cutter is 13 inches in diameter at the back ring.

Overview of the model dredge at the Haynes Coastal Engineering Laboratory

“If we made the screen opening size too small, sand would block it and suction pressure would decrease,” he said. “This would make the pump cavitate and stop the pump.”

Cavitation is when the pressure is reduced in the water such that the water boils or vaporizes. The pump is not designed to handle vapor.

Three graduate students, Joe Girani, Josh Lewis and Paulo de Oliveira, Jr., and Haynes Laboratory staff members John Reed and Kirk Martin assisted Randall in this research. They used different parameters such as cutter head rotational speed, ladder arm swing speed, pump flow rate, screen opening area ratio and screen opening shape to measure energy loss coefficients, pressure and production efficiency. This established the expected production rate and projected the time to complete dredging with the screen opening.

For a given area of the screen, they found that an opening of around 60 percent worked well. It kept the debris and ordnance out and allowed the sand to get through.

In a previous project at the laboratory, ropes were put in the sand and the area was dredged to see when the screen would plug up. Testing was conducted with a screen on the suction inlet to keep the ropes, which were simulating tree roots, from entering the suction inlet. Ropes clogged the screen and eventually choked off the pump.

Randall and the students measured the pressure drop between the inlet to the suction pump and the screen in front of the suction inlet of the pump as rope clogged the inlet.

According to the Department of Defense Environment, Safety and Occupational Health Network and Information Exchange (DENIX), munitions (unexploded ordnance) are present along the eastern shore of the United States and the Gulf of Mexico. Managing the explosive hazards in dredging operations is a critical safety concern.

“A screen with an optimum shape and size would not only maximize production but also protect the people onboard the dredge,” said Randall. “It can help prevent catastrophic accidents.”