Dr. Chao Ma, assistant professor in the Department of Engineering Technology and Industrial Distribution at Texas A&M University, is thinking small to make a big impact in the field of laser manufacturing.

How big?

Big enough to be used in a wide array of manufacturing disciplines, pharmaceutical processing, energy storage, biomedical implants and even outer space.

In a paper published in Nature Communications, Ma and a team of researchers from the University of California at Los Angeles and Missouri University of Science and Technology shared their success of using nanoparticles to create effective control of melting and solidification behaviors of materials.

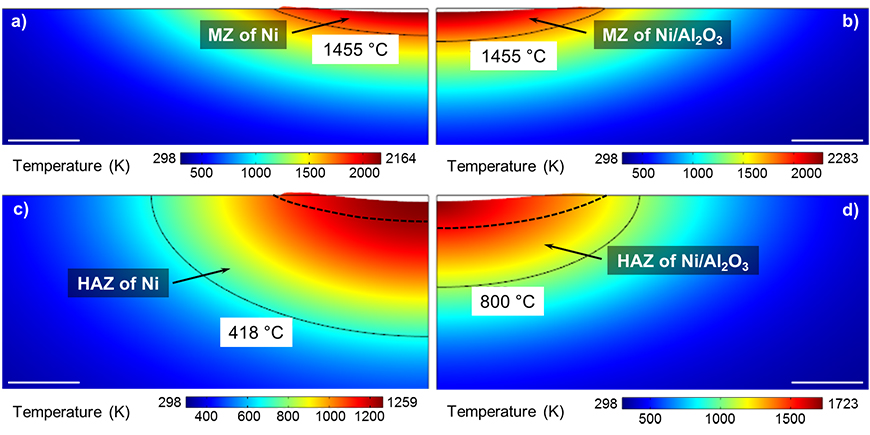

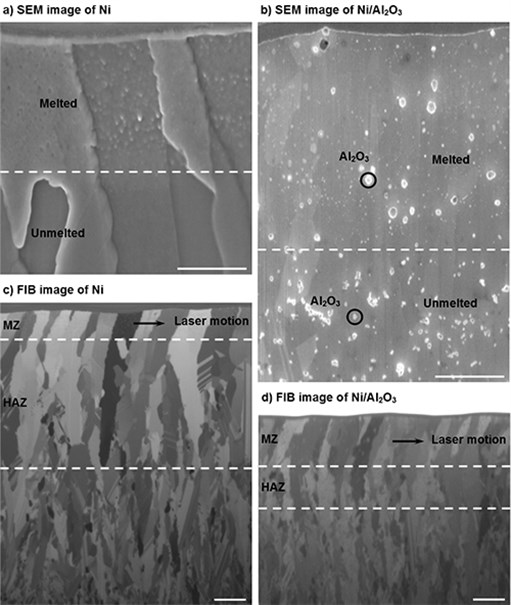

The dilemma facing laser manufacturing today is increasing the melted zone depth while simultaneously minimizing the heat-affected zone size during melting and solidification.

Typically, a larger melted zone leads to a larger heat-affected zone, weakening the overall material in the melting and solidification process. The material is fused, but the strength of the heat-affected structure decreases.

“We used nanoparticles to fine-tune thermophysical properties as well as melting and solidification behaviors,” said Ma. “The resulting material could be stronger and have a better surface finish.”

Specifically, Ma and his team added aluminum oxide nanoparticles to pure nickel, changing the way the nickel reacted to laser heat. The melted zone depth of the metal was increased by 68 percent while the corresponding heat-affected zone decreased by 67 percent.

These results provide a basic launching point of sorts for other researchers to use.

“We published this fundamental knowledge so a lot of people in the manufacturing field can use it in their own processes – we want to create an impact,” says Ma.

As a researcher into the transformative field of additive manufacturing, Ma is excited to utilize the department resources found at Texas A&M, specifically in the Manufacturing and Mechanical Engineering Technology (MMET) program in engineering technology and industrial distribution.

MMET’s new state-of-the-art Renishaw AM 400 is a powerful and flexible additive manufacturing machine that is the best of its kind in the world.

With Ma’s research and the Renishaw machine, Texas A&M can be a source for customized, nanoparticle-reinforced metal parts that could be used in outer space or even biomedical implants. Not only are the parts custom, so are their tailored microstructure.

The impact of this research goes far beyond Ma’s field of laser manufacturing, including laser welding, laser cutting and laser additive manufacturing,.

“[Our research] can be utilized in arc welding and electron beam manufacturing,” said Ma.

Ma stated that the microstructure phenomena his team is researching could be utilized outside of the manufacturing field, including pharmaceutical processing and energy storage.

With more research to come, Ma and his team are excited to say this is just the beginning of their exploration into advanced manufacturing’s newest discovery.