Most of us take flying in an airplane for granted. We book our tickets, sit through the long check-in lines, and if we’re lucky, take off on time to our chosen destination. Day in and day out we do this without any regard to the age and health of the airplane we’re flying on.

The airplanes that fly multiple flights a day incur wear and tear, such as cracks, in places not always easily seen. While there are standards and careful procedures in place to inspect aircraft for excessive wear and tear or minor defects, these important safeguards can be very expensive and time-consuming. A team of researchers at Texas A&M University is working to find a better method for detection of such cracks.

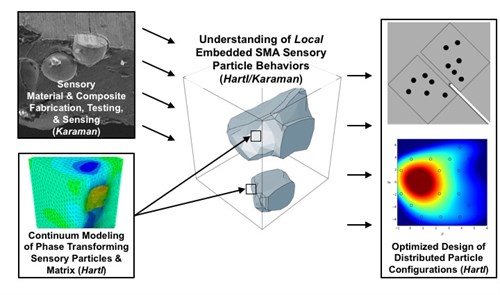

Dr. Darren Hartl, assistant professor in the Department of Aerospace Engineering and Dr. Ibrahim Karaman, department head and professor in the Department of Materials Science and Engineering at Texas A&M, have received a National Science Foundation (NSF) grant for nearly $400,000 to investigate the feasibility of embedding stress-sensitive active material particles into structural components to identify cracks the moment they occur. The project will be a part of the “Mechanics of Materials and Structures” program portfolio at the NSF.

Dr. Darren Hartl, assistant professor in the Department of Aerospace Engineering and Dr. Ibrahim Karaman, department head and professor in the Department of Materials Science and Engineering at Texas A&M, have received a National Science Foundation (NSF) grant for nearly $400,000 to investigate the feasibility of embedding stress-sensitive active material particles into structural components to identify cracks the moment they occur. The project will be a part of the “Mechanics of Materials and Structures” program portfolio at the NSF.

One of the greatest dangers to structural safety and reliability in airplanes is uncontrollable growth of cracks in unknown locations within the underlying material. Currently, aircraft must undergo scheduled inspections taking them out of service, and if necessary, additional downtime is needed for repair. This method has been effective, limiting the number of incidents associated with aircraft structural failure to just four percent of all accidents.

Unfortunately, these inspections are time-consuming and may be performed on an aircraft that is in minimal danger of structural failure, thus wasting time and manpower. On the other hand, standard inspections may not provide all the information needed to reveal underlying damage that can cause catastrophic failure later.

A fast and effective detection method that is unique to each individual aircraft and minimizes downtime would provide a more accurate description of the state of the aircraft. Utilizing a smarter monitoring system could result in an estimated 44 percent reduction in inspection time.

Recently, a nondestructive evaluation method has been proposed allowing for accurate crack detection in an aircraft or spacecraft structure. By strategically embedding stress-sensitive active material particles into structural components, the formation of cracks can be identified by detecting changes in the mechanical or magnetic responses of the embedded particles near such damage.

This method could allow earlier detection of cracks and other damage, and preclude the need for traditional inspection approaches. Each vehicle could be repaired on an as-needed basis saving time and money while gaining valuable information about how these aircraft behave in harsh environments.

Hartl and Karaman propose to use a composite they are developing in which single and polycrystalline magnetic shape memory alloy (SMA) sensory particles are embedded into aluminum alloys to detect cracks with the magnetic signals that emanate from these particles near the crack damage zone. Magnetic signature measurement is accurate and avoids false positives during operation.

Hartl and Karaman propose to use a composite they are developing in which single and polycrystalline magnetic shape memory alloy (SMA) sensory particles are embedded into aluminum alloys to detect cracks with the magnetic signals that emanate from these particles near the crack damage zone. Magnetic signature measurement is accurate and avoids false positives during operation.

SMAs are unique because the responses they exhibit are due to temperature, stress or magnetic field-induced phase transformation. As a crack forms, particles in the vicinity of the damage will transform between two different material phases. Both are solid, but they exhibit different properties so that the change from one to another can be detected using a number of different methods depending on the material.

The materials enabling this novel technology are a special sub-class of meta-magnetic SMAs (MSMAs), whose magnetic properties drastically change when they undergo a stress induced solid-solid martensitic transformation. The small size and wide distribution of the particles throughout the material should permit damage detection much earlier than existing technologies, leading to improved reliability and reduced costs.

A study will be carried out using models of embedded sensory particles, each model having varying particle sizes and densities. Model simulations will be used to determine which size and density configurations maximize transformation signal strength, while minimizing the effect that the particles have on overall performance of the material.

The focus of this research project will be on tailoring and fabricating specific sensory particle alloys and addressing the fabrication challenges for embedding these particles in aluminum alloys. Experiments will be performed to detect and interpret magnetic signals, developing an accurate model of the MSMA material behavior and designing sensory particle distributions for damage sensing at the component level.

The end goal is the effective magnetic detection of cracks, and the team hopes to demonstrate that phase-transforming sensory particles comprised of alloy systems exhibiting thermal-magnetic-mechanical couplings can be successfully embedded in aluminum components, and can be used to provide magnetic signatures during experiments where damage is introduced into these components.

Hartl says, “By combining the research strengths of my team with that of Ibrahim’s, I have no doubt that some important developments will result from this new support.”