Even astronauts have to do the laundry.

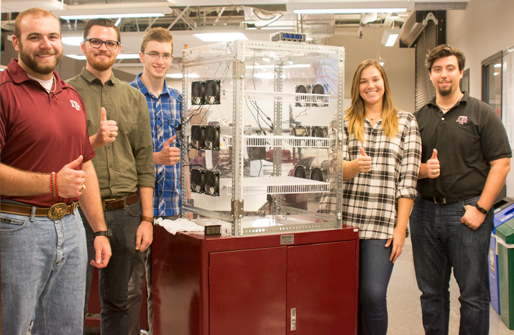

Five seniors from the Department of Mechanical Engineering at Texas A&M University are working together to develop clothes dryer technology to help astronauts save on clothes and supplies during future long-term missions.

Five seniors from the Department of Mechanical Engineering at Texas A&M University are working together to develop clothes dryer technology to help astronauts save on clothes and supplies during future long-term missions.

“The possibility that our dryer could go into space on the Mars mission is really awesome,” said team member Mason Herpin.

The project is the team’s senior capstone design project, which aims to bridge the gap between classroom and industry by requiring students to use their knowledge and skills to complete an engineering design project. The NASA team in MEEN 402 have been working since January to develop a clothes dryer prototype that will work in space.

“Currently what they do with the clothes is they wear them once, they put them back in a supply pod, and the supply pod is designed to burn up on reentry because they don’t have any way to wash and dry clothes in space right now,” said team member Nicholas Hill.

The prototype dryer uses forced evaporation to dry the clothes, with 12 fans blowing air over the material. To test the design, the team dries a dry-fit t-shirt, a pair of gym shorts and a thick pair of cotton socks, an outfit similar to an astronaut’s workout gear.

So far, the team has run the test for two hours at the most, running at about 30 watts of power. The teams allowable power usage, 150 watts, is a tenth of an average hair dryer.

One major obstacle the students have to tackle is developing something that will function in zero gravity, a challenge difficult to test at Texas A&M’s Engineering Innovation Center.

“When you’re in zero gravity, if you have a big barrel rotating inside a spaceship, the angular momentum of the ship will change,” said team member Casey Peterson. “That will throw off the trajectory of the spaceship, so that was one of the biggest issues we had to work through.”

The team is also working on an adjacent project to develop a long-term trash stowage system that can be used on longer voyages. Currently, trash is handled similarly to dirty laundry — loaded into a supply pod and burned in the atmosphere. However, on a longer mission astronauts have to consider space and the possibility of bacterial growth. The team has developed a box that food vacuum bags can be placed in and compressed. As the bags are vacuum compressed, an opening in the compactor allows astronauts to heat seal the bags.

Team member Julia DeVinney said the team has considered how either prototype, or something similar, could be have broader uses.

“Even though this is something we’re working on for NASA, maybe this dryer could also be used in many different applications,” DeVinney said.

The senior capstone program is meant to help students develop skills needed to succeed in diverse industry design teams. All of the NASA team members agreed that teamwork was a large component of the learning experience.

“It’s been a really good learning experience for all of us too, because this is kind of how projects work in industry. Everyone has got a different schedule and everyone has different meetings going on at different times and different places they have to be,” said project manager Bailey C. Robbins. “Being able to work together or separate to get the same end goal and bring it together is great experience.”

The team members are expected to present a final presentation of their prototypes to NASA officials in Houston in December.

For more information about the capstone program, email Dr. Joanna Tsenn at joanna.tsenn@tamu.edu.