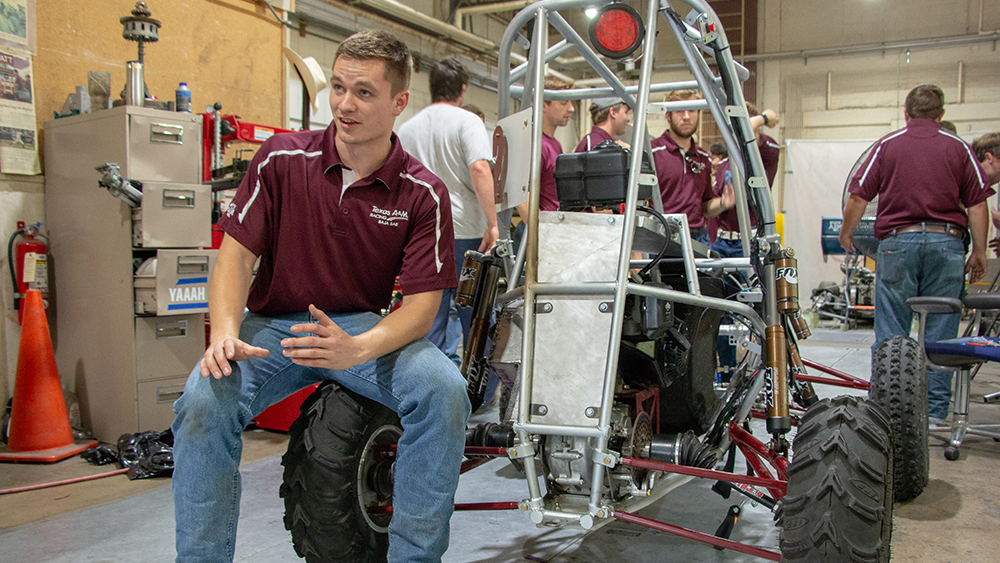

Hard work, preparation and teamwork helped build the foundation for the inaugural Texas A&M University Baja SAE team's strong overall finish at its first competition, according to project manager William Swain.

The student team traveled to Pittsburg, Kansas, May 17-20 to compete as one of 95 teams in its debut appearance. The Aggies finished with an overall ranking of 33rd. Among the team’s best rankings for individual events included7th place for maneuverability, 25th for acceleration, 26th for design and 27th for endurance.

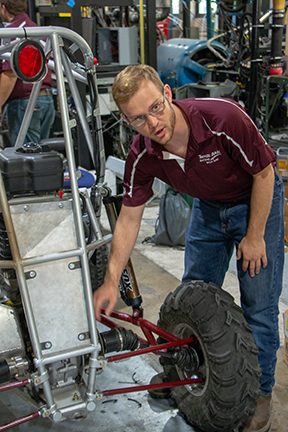

Under the SAE International Collegiate Design Series, the Baja SAE competition tasks student teams with designing and building a single-seat, all-terrain vehicle with the purpose of serving as a prototype for a “reliable, maintainable, ergonomic and economic production vehicle that serves a recreational user market,” according to competition guidelines.

“For a first-year team, our competition results were impressive and did not happen by accident,” said Swain, who will be a senior in the Department of Mechanical Engineering this fall. “The car we dreamt of and designed on paper became a reality andcompeted toe to toe with teams that had 20 years of experience in the competition. It was a great accomplishment.”

Team co-advisor and mechanical engineering professor of practice Dr. Swaminathan Gopalswamy, who traveled with the team for the competition, said he was pleased by the team’s performance.

“Most people who saw our car were extremely impressed to also learn that we were a first-year team,” Gopalswamy said. “There were many other experienced universities who were still working to put together or fix their cars at the last minute.”

He said the team’s hard work was evident in the results, and that he was personally approached by one of the design competition judges to congratulate them on their showing.

He said the team’s hard work was evident in the results, and that he was personally approached by one of the design competition judges to congratulate them on their showing.

In addition to the team’s achievements in the competition, Gopalswamy said he was also proud of the way in which the students represented Texas A&M.

“I found the sportsmanship and camaraderie at the competition very satisfying,” he said. “The students were very willing to help other competitors and made many good friends in the process.”

Swain said they initially formed last spring out of the Texas A&M Racing Apprentices program. The team, which ultimately grew to include 27 sophomore and junior students, consisted of five subteams, which focused on the powertrain, electrical, suspension, chassisand business, respectively.

Although building the new program required a substantial commitment from team members to balance the demanding work with full course loads over the past year, he said it was ultimately a rewarding experience that gave them practical skills for their future careers.

“It's been a really great team experience,” Swain said. “It's a simulation of a real-world work environment because you're working on a project with deadlines and only a certain amount of money. It's a really hands-on, low-risk simulation of a work environment.”

Swain specifically praised the opportunities to interact with industry representatives as instrumental to the experiences they gained in the team’s first year.

“Our exposure to companies has been unreal,” he said, adding that the team also had the opportunity to present to and interact with the mechanical engineering department’s industry advisory council twice throughout their time working on the project.

Dr. Srikanth Saripalli, associate professor in the mechanical engineering department and co-advisor for the Baja team, said it has been a pleasure to watch the group of studentsdevelop and grow over the past year. In particular, he was impressed with the amount of information the students had gathered on other teams across the country and their focus on building a first-year program poised to continue growing in the years to come.

“The entire team has been very organized, methodical and focused,” Saripalli said. “Given that this is a student-led team without any class associated with it, I am amazed at their progress and their enthusiasm. With minimal effort from the faculty, they now have a fully working car. I think the team put in a tremendous amount of hard work.”

“The entire team has been very organized, methodical and focused,” Saripalli said. “Given that this is a student-led team without any class associated with it, I am amazed at their progress and their enthusiasm. With minimal effort from the faculty, they now have a fully working car. I think the team put in a tremendous amount of hard work.”

Gopalswamy said he has also been proud of the team for overcoming the various challenges placed in their way throughout the process of building their car.

“They have overcome not just technical challenges, but societal and cultural challenges that start arising when a group of people comes together through self-governance,” he said.

Gopalswamy and Saripalli view the students’ experiences throughout the project as the basis for several life-long lessons, including responsibility, understanding, teamwork, self-initiative and confidence, as well as the real-world experience of engineering a vehicle while conforming to requirements, deadlines and a limited budget.

On behalf of himself and his team, Swain is grateful for the support of the mechanical engineering department.

“We honestly could not have done it without the department, our two faculty advisors, our sponsors and the resources at Thompson,” Swain said. “Without them, this wouldn't have been possible.”

He also believes the next team, equipped with the lessons of the group’s inaugural year — including the time necessary for fabrication and manufacturing, as well as the costs associated with the project — will be poised to achieve even more at the next Baja SAE competition in 2019.

“There were quite a few bumps in the road, but for a first-yearteam it went relatively smoothly. We started every meeting with a team prayer asking for protection and guidance, and things just fell into place.” Swain said. “When we started we had no idea about the time it would actually take or the amount of money we would need. Those were our two main challenges. Passing on that information to the next team is valuable. Those two things will give them a better understanding of how to manage the project.”

Click here to learn more about the Texas A&M Baja SAE team.

The student team traveled to Pittsburg, Kansas, May 17-20 to compete as one of 95 teams in its debut appearance. The Aggies finished with an overall ranking of 33rd. Among the team’s best rankings for individual events included

Under the SAE International Collegiate Design Series, the Baja SAE competition tasks student teams with designing and building a single-seat, all-terrain vehicle with the purpose of serving as a prototype for a “reliable, maintainable, ergonomic and economic production vehicle that serves a recreational user market,” according to competition guidelines.

“For a first-year team, our competition results were impressive and did not happen by accident,” said Swain, who will be a senior in the Department of Mechanical Engineering this fall. “The car we dreamt of and designed on paper became a reality and

Team co-advisor and mechanical engineering professor of practice Dr. Swaminathan Gopalswamy, who traveled with the team for the competition, said he was pleased by the team’s performance.

“Most people who saw our car were extremely impressed to also learn that we were a first-year team,” Gopalswamy said. “There were many other experienced universities who were still working to put together or fix their cars at the last minute.”

He said the team’s hard work was evident in the results, and that he was personally approached by one of the design competition judges to congratulate them on their showing.

He said the team’s hard work was evident in the results, and that he was personally approached by one of the design competition judges to congratulate them on their showing. In addition to the team’s achievements in the competition, Gopalswamy said he was also proud of the way in which the students represented Texas A&M.

“I found the sportsmanship and camaraderie at the competition very satisfying,” he said. “The students were very willing to help other competitors and made many good friends in the process.”

Swain said they initially formed last spring out of the Texas A&M Racing Apprentices program. The team, which ultimately grew to include 27 sophomore and junior students, consisted of five subteams, which focused on the powertrain, electrical, suspension, chassis

Although building the new program required a substantial commitment from team members to balance the demanding work with full course loads over the past year, he said it was ultimately a rewarding experience that gave them practical skills for their future careers.

“It's been a really great team experience,” Swain said. “It's a simulation of a real-world work environment because you're working on a project with deadlines and only a certain amount of money. It's a really hands-on, low-risk simulation of a work environment.”

Swain specifically praised the opportunities to interact with industry representatives as instrumental to the experiences they gained in the team’s first year.

“Our exposure to companies has been unreal,” he said, adding that the team also had the opportunity to present to and interact with the mechanical engineering department’s industry advisory council twice throughout their time working on the project.

Dr. Srikanth Saripalli, associate professor in the mechanical engineering department and co-advisor for the Baja team, said it has been a pleasure to watch the group of students

“The entire team has been very organized, methodical and focused,” Saripalli said. “Given that this is a student-led team without any class associated with it, I am amazed at their progress and their enthusiasm. With minimal effort from the faculty, they now have a fully working car. I think the team put in a tremendous amount of hard work.”

“The entire team has been very organized, methodical and focused,” Saripalli said. “Given that this is a student-led team without any class associated with it, I am amazed at their progress and their enthusiasm. With minimal effort from the faculty, they now have a fully working car. I think the team put in a tremendous amount of hard work.”Gopalswamy said he has also been proud of the team for overcoming the various challenges placed in their way throughout the process of building their car.

“They have overcome not just technical challenges, but societal and cultural challenges that start arising when a group of people comes together through self-governance,” he said.

Gopalswamy and Saripalli view the students’ experiences throughout the project as the basis for several life-long lessons, including responsibility, understanding, teamwork, self-initiative and confidence, as well as the real-world experience of engineering a vehicle while conforming to requirements, deadlines and a limited budget.

On behalf of himself and his team, Swain is grateful for the support of the mechanical engineering department.

“We honestly could not have done it without the department, our two faculty advisors, our sponsors and the resources at Thompson,” Swain said. “Without them, this wouldn't have been possible.”

He also believes the next team, equipped with the lessons of the group’s inaugural year — including the time necessary for fabrication and manufacturing, as well as the costs associated with the project — will be poised to achieve even more at the next Baja SAE competition in 2019.

“There were quite a few bumps in the road, but for a first-year

Click here to learn more about the Texas A&M Baja SAE team.