When it comes to walking with a transfemoral prosthetic, it’s a lot harder than it looks. Traditional transfemoral (above the knee) prosthetics are passive, or semiactive, meaning they are made up of a single metal rod that is able to bend a little bit, but does not give the wearer a full range of motion or the ability to change their walking pattern. Without either of those features, walking can become a tedious job when it comes to dealing with various terrains, going downhill or walking up and down a set of stairs. To help make daily life easier for amputee patients, Dr. Pilwon Hur, assistant professor in the J. Mike Walker ’66 Department of Mechanical Engineering at Texas A&M University, has developed a robotic transfemoral prosthesis.

Hur became interested in the topic of rehabilitation robotics when he was studying biomechanics and neuromechanics for his Ph.D. With a degree in mechanical engineering and a personal interest in mechatronics (a hybrid of mechanical, electrical and computer engineering) and robotics, he already had an extensive knowledge in the technical side of the issue. However, it was not until he was in the midst of completing his dissertation that he was inspired to take his research a step further.

“I was trying to understand how humans move and why we move this way, and how I could use this information to help people who are disabled,” said Hur. “Since I was interested in walking and balance, I figured I should work in that area for rehabilitation. So when I was doing my post doctorate, I mostly worked with stroke patients and learned a lot about rehabilitation robotics at that time.”

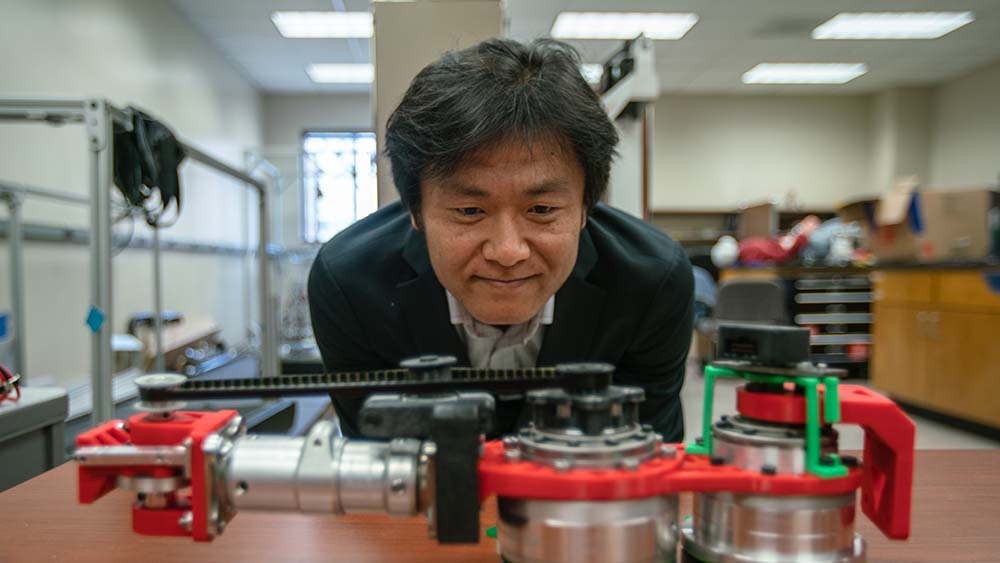

His design is focused on addressing the weight of the prosthesis because one of the main reasons many amputee patients dislike robotic prosthetics is because they are too heavy to maintain any sort of natural movement. His design uses series elastic actuators, which is a spring that can be added to the motor of a robotic device used to control force and increase shock tolerance and compliance with the surrounding environment. It is an existing technology, but Hur took a different perspective to use a rotary spring that will help reduce the device’s weight as well as control the system more effectively, making it easier for the wearer to handle and walk.

“We’re optimizing the design of the structure so that we can minimize the weight, and so that we can cut off some parts which, based on our analysis, are not necessary so that we can make it lighter,” said Hur. “We can lower the specs of the motor, allowing us to use a much lighter motor to achieve the same goal. The spring saves energy and that energy can be used to control the system, so the use of battery power is minimized.”

In addition to the device as a whole, Hur is working to develop a new design for the foot, one that will replicate the rolling behavior of the foot joints and allow the foot to bend like a regular one. It will help give patients a more natural feel. He is in the process of conducting tests in the lab to see if this tool will enhance the bioperformance of the prosthesis.

Hur is currently searching for a commercial partner to license this technology, manufacture it, conduct the necessary testing and get it to the market for consumers. The Texas A&M Engineering Experiment Station’s Commercialization and Entrepreneurship Office is ready to offer licensing terms for the intellectual property corresponding to the technology.

While the market for the device may not be huge, Hur believes that it will help amputees navigate their world without being weighed down by a prosthetic.

“What I hope to achieve with this technology is for amputee patients to walk without any worry or hesitation, and just live their lives without any difficulties,” said Hur.