Texas A&M University, through its unique Engineering Medicine (EnMed) partnership with Houston Methodist Hospital, is stepping up to help the health care system keep up with the demand for medical supplies brought on by the increasing number of confirmed and suspected COVID-19 cases.

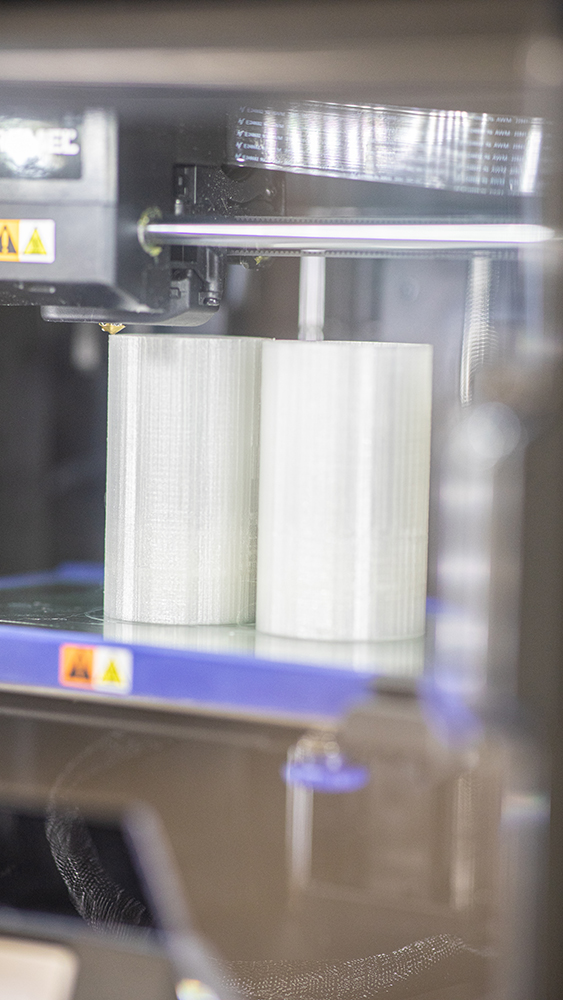

A team led by Dr. Michael R. Moreno has already delivered 200 3D-printed diffusers for metered dose inhalers (MDI) to the Houston hospital and stands ready to produce more if needed.

“The spacer, or diffuser, that we created will allow the doctors to use metered dose inhalers to treat diagnosed and suspected COVID-19 patients who are not yet in need of ventilator therapy, without using nebulizers that may aerosolize the virus,” Moreno said. “And this is important because if this early stage intervention is effective, then it is possible that these patients may recover before reaching that critical point where ventilator therapy is required.”

Moreno, assistant professor in the J. Mike Walker ‘66 Department of Mechanical Engineering and director of innovation for Engineering Medicine, said the hospital was facing a critical shortage after being unable to find the diffusers from its normal suppliers.

He said one of the most powerful aspects of the project is that it came from direct communication with doctors who, at the forefront of this crisis, are identifying emerging unanticipated needs.

“In some cases, the solutions are not that complicated, but you have to know that the problems exist,” Moreno said. “And the only way you’re going to know that as an engineer is if you have an open line of communication with the doctors.”

While ventilators are reserved for patients experiencing severe symptoms, respiratory inhalers are a part of the early treatment plan for most hospitalized patients exhibiting signs of COVID-19 infection.

Bronchodilator drugs used for treatment of asthma can be utilized in COVID-19 patients to improve their ability to breathe. In the hospital setting, these would typically be administered using nebulizers. The concern is that the use of nebulizers could aerosolize the virus, placing those in the area at higher risk of contracting the disease.

Consequently, inhalers are the preferred method of delivery for these drugs with confirmed and potential COVID-19 patients. The inhaler devices require precise timing of inhalation for proper delivery to the lungs, which is something Moreno said even experienced users, like himself, can find challenging.

With the help of a diffuser, patients are better able to get more of the medication into their lungs.

“These spacers work like diffusers and allow the patient more time to draw the entire dose of medication into their lungs” Moreno said. “And when you're suffering from respiratory illness, this may be very important.”

Engineers are great at solving problems that benefit society and the health care delivery system, right now, is very much in need of help with problem solving as we struggle with this pandemic and all of its associated challenges

Although Metzen said nebulizers could also be used to administer the medication, metered dose inhalers are preferred due to a concern that nebulizers used by patients with COVID-19 in the hospital could spread the virus.

Houston Methodist has a partnership with the Texas A&M College of Medicine and College of Engineering through the EnMed program, an integrated educational and research medical program with a focus on innovation. Dr. Roderic Pettigrew, executive dean of EnMed, said this rapid response by Moreno and his team to develop a use-inspired solution in the 3D printed diffuser serves as a perfect example of the program’s concept in action.

“Engineers are great at solving problems that benefit society and the health care delivery system, right now, is very much in need of help with problem solving as we struggle with this pandemic and all of its associated challenges,” Pettigrew said. “EnMed has risen to the occasion right here in Houston to serve people in need. We’re working with our colleagues at Houston Methodist Hospital in order to devise practical solutions to real problems on the front lines of treating COVID-19 patients.”

Although the concept being utilized for the diffusers is not new, this is among the first times it has been locally 3D printed and delivered on this scale.

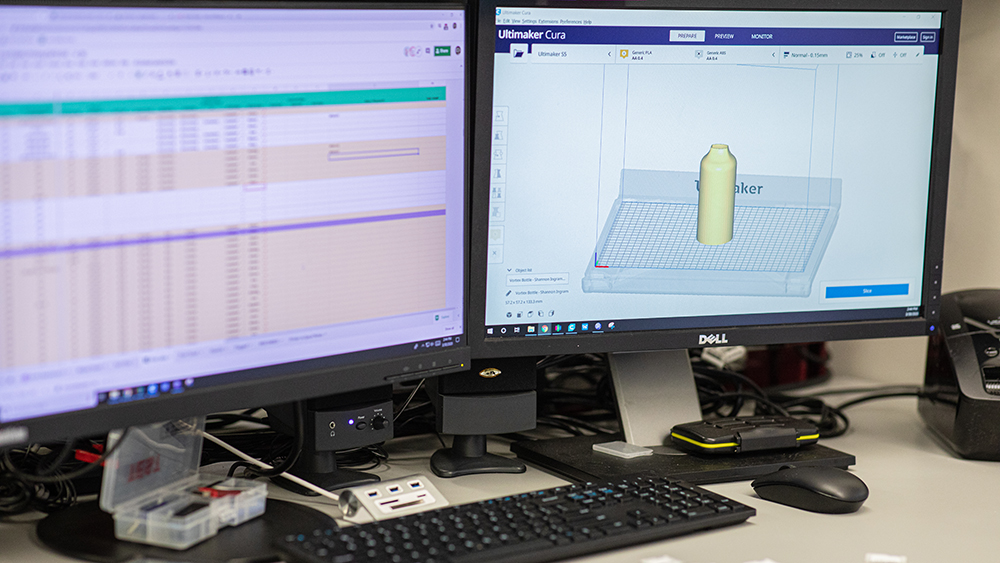

Anticipating that this shortage is likely not unique to Houston Methodist, Moreno and his team are making the stereolithography (STL) file for the 3D-printable design publicly available at no cost on the EnMed website.

“People will be able to go to the site, download those STL files and then print these spacers for their local hospitals as well, if they find that they have need for it,” Moreno said.

Additionally, the team has designed an alternate, smaller 3D-printable device designed for areas that may be more resource limited. This device is essentially an inhaler interface that allows one to use a common plastic water bottle as the diffuser chamber.

Moreno said his team, as well as several others throughout The Texas A&M University System, have worked tirelessly to make sure they would be able to deliver the diffusers to patients in need as soon as possible.

“As an Aggie biomedical engineer and mechanical engineer working in this biomedical space, times like these are when we really want to rise to the challenge,” Moreno said. “Right now, there are patients that are using these spacers, or diffusers, and we’re very hopeful about addressing future problems as well. This is just what we do as Aggie engineers.”