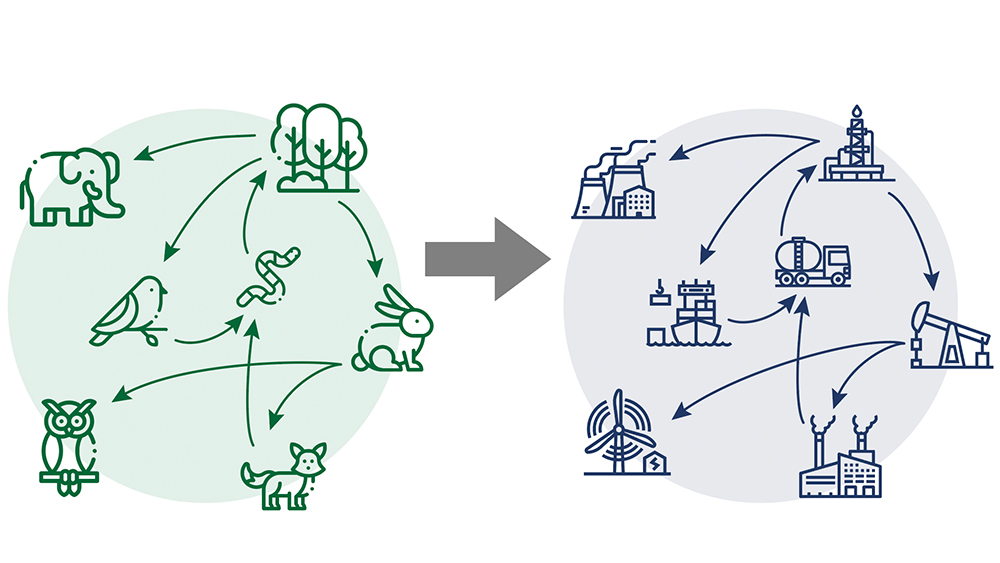

By translating the pattern of interconnections between nature’s food chains to industrial networks, researchers at Texas A&M University have delineated guidelines for setting up successful industrial communities. The researchers said this guidance can facilitate economic growth, lower emissions and reduce waste while simultaneously ensuring that partnering industries can recover from unexpected disturbances.

“Industries can often partner up to exchange byproducts and over time these industries might form bigger communities. While these networks sound quite beneficial to all industry partners within the community, they are not always successful,” said Dr. Astrid Layton, assistant professor in the J. Mike Walker’ 66 Department of Mechanical Engineering. “We tried to solve this problem by providing design guidelines inspired by nature’s food webs so that the overall system will be both eco-friendly and save money for everyone.”

The researchers published their study in the journal Resources, Conservation & Recycling.

An essential part of running any industry is identifying resources, such as raw materials, that are economically viable. Rather than having each industry work out these details independently, an eco-industrial park or a network of partnering industries is an emerging trend. Further, businesses belonging to these parks work symbiotically where, much like in nature, industries mutually benefit from each other. For example, one industry’s waste is another one’s raw materials — often saving both partners money.

When successful, industrial symbiosis can help to reduce raw material use, costs and emissions while generating sizeable financial returns. However, there have also been instances where eco-industrial parks have not worked.

“When eco-industrial parks started to show success, people took note and began trying to form their own community of companies that exchanged byproducts, but these ‘from-the-ground-up’ designs can be hit or miss,” said Layton. “The underlying reasons could be many, perhaps economic or if, for instance, one company goes bust, the whole system breaks down because they’re all connected.”

To combat this problem, the researchers sought to provide guidelines on how best to design these industry communities to leverage the benefits of industrial symbiosis while avoiding the downfalls.

For their analysis, Layton and her team referred to food webs that are both resilient to disturbances and produce minimal waste. These biological networks are made up of multiple food chains linking predators and preys. Furthermore, the organization of the interconnected chains in food webs has been extensively studied over the years using quantitative measures. Of the many metrics, the researchers were especially interested in one called nestedness.

This metric, which ranges from 0 to 1, reflects the location where connections are occurring within networks. When nestedness has values closer to one, there is a hierarchy in the connections, in other words, one actor is connected to all other actors in the network, another actor is connected to a subset of those, and so on. For example, a highly nested structure would be one where certain species of bees pollinate a variety of plants while other “specialist” bees pollinate only a small number of plants within this much wider set. Alternatively, poorly nested structures have values closer to zero and every actor in the network may be connected to every other.

But unlike food webs, many industrial networks have been shown to have low nestedness. So, the researchers tested if increasing the nestedness in industrial networks could promote the financial benefit and the ability for industries to recover from disturbances.

For their study, Layton and her team included nine industries, including a fertilizer plant, a pharmaceutical plant and a wastewater treatment facility, that could participate in five types of water-based exchanges. Next, they created 4000 different network designs, broken up into 200 designs at 20 different nestedness values.

They found that when the network design had high nestedness, freshwater usage was less and the network survived unforeseen disturbances, which ultimately translated to more savings and resource conservation. They also found in more specific scenarios, such as when the industries were spread out geographically and the resources are very expensive, high nestedness in industry networks was again more advantageous.

The researchers noted that they analyzed only water exchanges in the current study and their future work will address other types of resource exchanges and environmental impacts. However, they said the benefit of high nestedness in industrial networks was generalizable to other exchanges as well.

“Water is the worst-case scenario compared to other exchange products in terms of infrastructure costs,” said Layton. “Our results have identified situations when high nestedness is an advantage, which can then guide the design of the network. This work will support success both from an economic perspective and resilience perspective.”

Abheek Chatterjee and Colton Brehm from the mechanical engineering department also contributed to this research.