Additive manufacturing techniques used to produce metal alloys have gained popularity due to their ability to be fabricated in complex shapes for use in various engineering applications. Yet the majority of studies conducted have centered around developing single-phase materials.

Dr. Kelvin Xie’s team in the Department of Materials Science and Engineering at Texas A&M University employed advanced characterization techniques to reveal the microstructure of the 3D-printed dual-phase multi-principal elements, also known as high entropy alloys (HEAs), that display ultra-strong and ductile properties. This work is a collaboration with Dr. Wen Chen from the University of Massachusetts at Amherst and Dr. Ting Zhu from the Georgia Institute of Technology.

This study was recently published in Nature.

The HEA reported in this study was fabricated through laser powder bed fusion (L-PBF) at the University of Massachusetts at Amherst. L-PBF is the process of heating and cooling materials at very fast rates, which allows the creation of unique microstructures and tailoring of mechanical properties. However, researchers have largely focused on using L-PBF for single-phase materials.

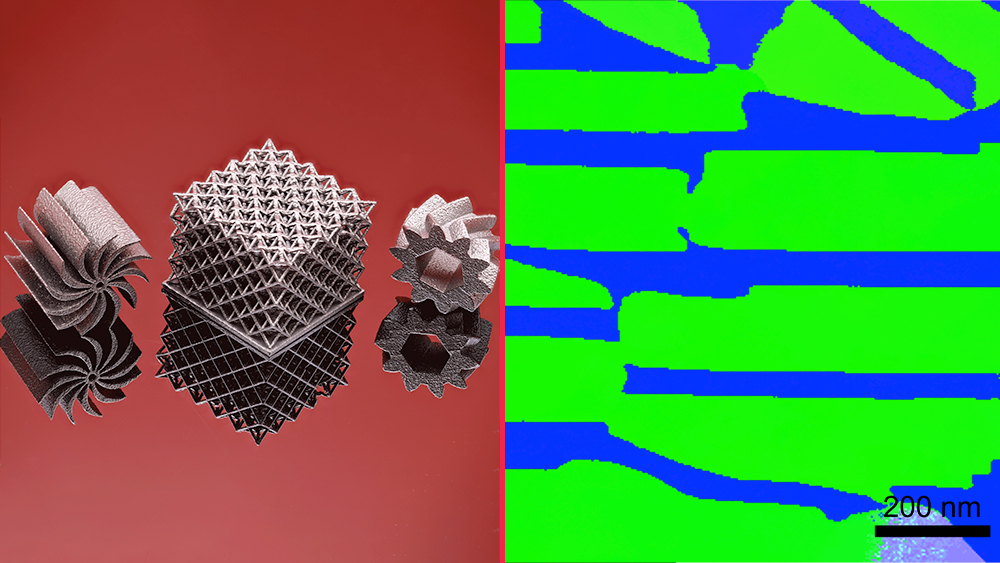

In this work, Xie and his graduate student Dexin Zhao led the characterization effort to understand 3D-printed dual-phase eutectic HEAs. Rather than being composed of a single phase, dual-phase HEAs are layered in a self-organized structure at the nanoscale.

“A eutectic alloy is similar to a lasagna,” said Xie. “First, you have a sheet of pasta, then sauce, meat and cheese. These layers repeat. In materials, the face-centered cubic phase and body-centered cubic phase are like sheets of pasta and the filling.”

The interfaces separating these phases are strong barriers that provide additional strength. The super-fast cooling rate, which is unique to L-PBF 3D printing, created the super fine “pasta sheets” and “filling.” This creates exceptionally high-density interfaces that are critical to the combination of excellent strength and ductility.

According to Xie, this is the first time that the researchers achieved the 3D-printed, nanostructured HEA that displays both ultra-strong and ductile properties, a difficult feat to overcome in materials science due to the opposing nature of these characteristics.

In addition to its favorable physical properties, when used in applications like aerospace or automobiles, this material offers the potential to decrease energy costs.

“Wherever energy is consumed, there is a concern,” said Xie. “For example, a car moving passengers consumes way more energy moving itself than it does moving the passengers. Our findings show new avenues for materials design, which eventually can lead to lightweight alternatives to many of the materials we currently use in manufacturing.”

In the future, the researchers hope to harness this technology for various engineering applications and manufacturing materials that must be lightweight while resisting deformation.

This research is funded by the National Science Foundation and Lawrence Livermore National Laboratory. It is a collaborative effort between the University of Massachusetts at Amherst, the Georgia Institute of Technology, the University of California, Los Angeles, Rice University, and the Oak Ridge and Lawrence Livermore National Laboratories.