From aircraft and trains to gas compressors and tanks, turbine engines play an essential role in our everyday lives. Often used in extreme environments, turbines are developed from refractory alloys that can withstand extraordinarily high temperatures. However, the manufacturing process for creating turbines can be challenging and costly.

Dr. Raymundo Arróyave, Segers Family Dean’s Excellence Professor in the Department of Materials Science and Engineering at Texas A&M University, and a team of researchers were recently awarded a $1.8 million grant from the National Science Foundation to develop and demonstrate a framework capable of rapidly discovering new alloys. In particular, the framework shows potential to discover refractory alloys that operate at higher temperatures while also finding materials suitable for 3D-printing, allowing for the rapid manufacturing of parts and components of next-generation turbine engines.

The project is entitled “DMREF: Optimizing Program formulation for prinTable refractory alloys via Integrated MAterials and processing co-design (OPTIMA).”

“Our field of materials science is evolving quite rapidly, and currently, the emphasis is on the development of methods to accelerate materials discovery,” said Arróyave. “The motivation for this is the pressing need to rapidly solve important technological challenges with profound societal implications, including more efficient power generation and transportation.”

To approach this issue, the researchers are using a highly interdisciplinary approach combining machine learning, artificial intelligence, optimization, manufacturing, metallurgy and computer simulations to discover printable refractory (temperature-resistant) alloys.

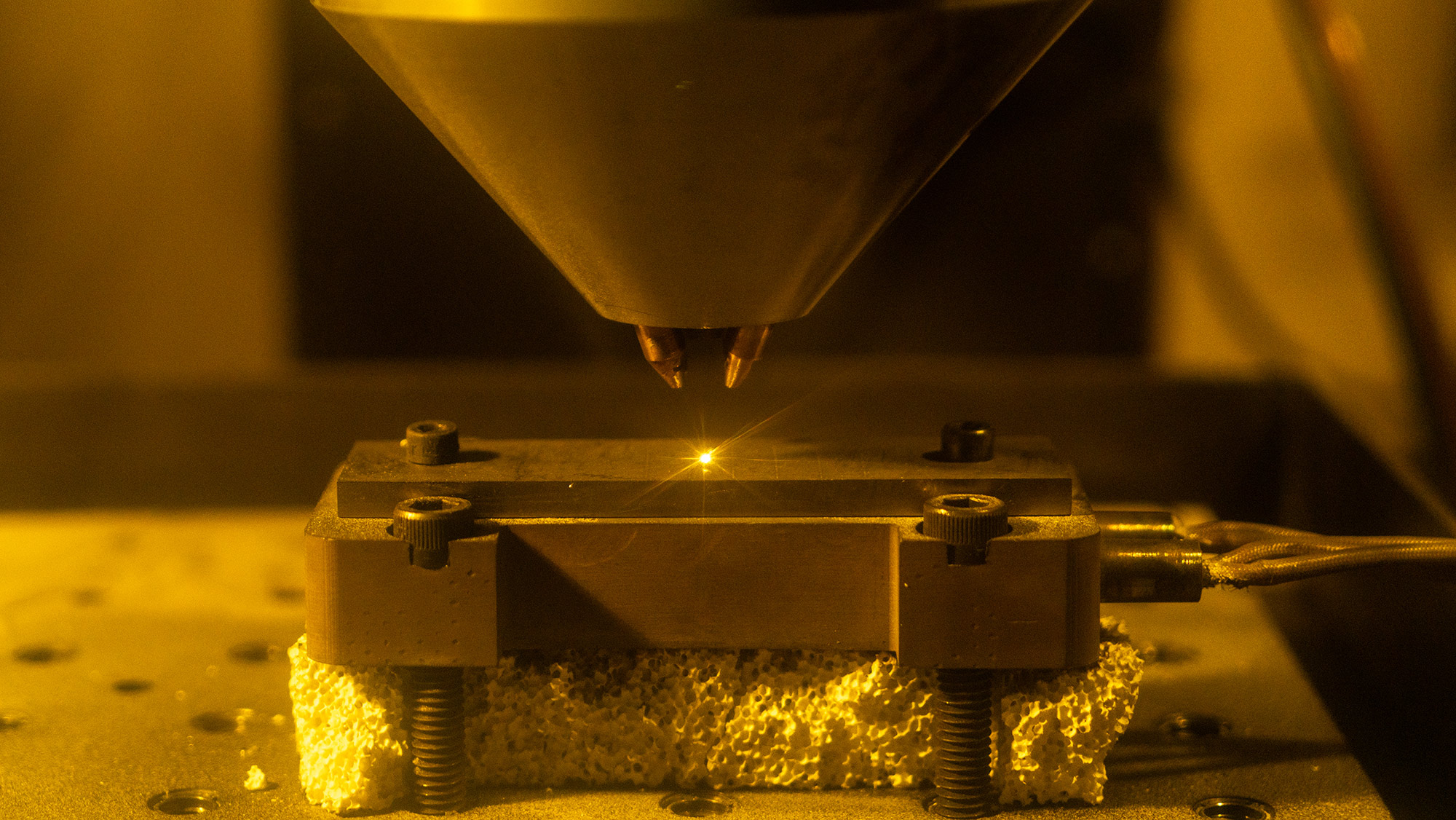

The greatest attribute of these refractory materials is their most significant challenge: since these materials retain outstanding strengths at extremely high temperatures, the only way in which they can be manufactured into complex shapes is through 3D printing.

According to Arróyave, the key innovation in their technique that differs from other advanced approaches to materials discovery is that existing approaches assume that the materials designers know the parameters for optimization. In contrast, this new approach proposes to discover the problem, or what properties need to be optimized, during the materials discovery process.

“Our approach is much more flexible than other approaches and allows for rapid change or pivoting considering new information,” said Arróyave. “For example, our approach can design alloys that avoid the use of a particular ingredient that initially is thought to be too expensive. If the conditions change, our framework is capable of immediately re-formulating the materials discovery problem and carrying on with the optimization in a seamless manner.”

Even though the materials space is time-consuming and expensive to explore, this new robust framework could power autonomous materials development at much lower costs in reduced timeframes. The process will allow the researchers to find alloy compositions with desired characteristics, such as temperature resistance, malleability, strength and ductility. In addition, they could tailor the alloys to be suited for printing, creating a pathway to print parts and components of turbine engines that can be safely used in extreme environments.

“We hope that this project will provide us with answers to deep questions about what important characteristics are necessary to render materials resistant to high temperatures,” said Arróyave.

Once the optimal material is discovered, the researchers will investigate the needed processing protocols so the material can be 3D printed into a complex shape such as those of turbine blades.

“The greatest attribute of these refractory materials is their most significant challenge: since these materials retain outstanding strengths at extremely high temperatures, the only way in which they can be manufactured into complex shapes is through 3D printing,” said Arroyave. “Finding alloys that have superior mechanical properties while being ‘3D-printable’ is what makes this project very challenging and simultaneously stimulating.”

This research is in collaboration with Dr. Alaa Elwany, associate professor in the Wm Michael Barnes ’64 Department of Industrial and Systems Engineering, Dr. Ibrahim Karaman, head of the Materials Science and Engineering department and Dr. Douglas Allaire, associate professor in the J. Mike Walker ’66 Department of Mechanical Engineering. Additionally, the team collaborated with Dr. Brady Butler from the United States Army Research Laboratory.