Story Overview

A team of researchers from the Texas A&M Energy Institute and the Artie McFerrin Department of Chemical Engineering led by Dr. Mahmoud El-Halwagi are developing novel technologies and integrated systems that could dramatically reduce the amount of water needed in the natural gas extraction process.

Researchers from the Texas A&M Energy Institute and the Artie McFerrin Department of Chemical Engineering are leading a major initiative to reduce the amount of water needed in the natural gas extraction process, and to treat wastewater so that it is safe for reuse. Since the early 2000s, hydraulic fracturing has been the main natural gas extraction process in the United States. The effectiveness of the process and the access to major reserves have led to substantial economic growth through the use of shale gas in generating electricity and in producing a wide variety of value-added chemicals. While hydraulic fracturing is extremely effective, the process requires large amounts of water, which typically ranges from two to seven million gallons per well. After this water is used in the extraction process, it returns to the surface as wastewater, containing naturally occurring contaminants like radium, salts, metals and various chemicals used in the process. This wastewater is usually shipped offsite for treatment or injected into a deep well for disposal.

The potential impact on industry and everyday life is tremendous. “The project will enhance the quality of life for communities adjacent to shale gas production, will provide a strategic roadmap for the cost-effective management of shale gas wastewater, and will help gas producers operate in more sustainable manner,” said Dr. Mahmoud El-Halwagi.

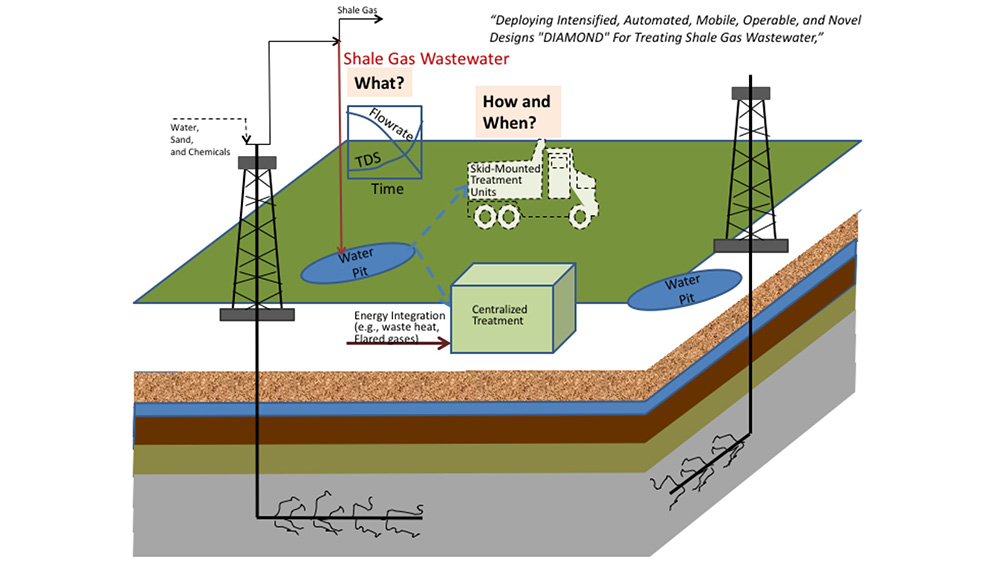

El-Halwagi is professor, holder of the Bryan Research and Engineering Chair in Chemical Engineering and managing director of the Texas A&M Engineering Experiment Station’s Gas and Fuels Research Center (GFRC) is the principle investigator (PI) of a Department of Energy (DOE) research project entitled, “Deploying Intensified, Automated, Mobile, Operable and Novel Designs (DIAMOND) for Treating Shale Gas Wastewater,” focused on developing integrated design and operating approaches for modular systems that can be deployed in the treatment of hydraulic fracturing wastewater.

The team of Texas A&M researchers is collaborating on this $5.3 million project with partners from the University of Pittsburgh, The University of Texas at Austin, and U.S. Clean Water Technology. “The project is aimed at developing novel technologies and integrated systems that will lead to a paradigm shift in managing shale gas wastewater, reducing cost, conserving natural resources, and enhancing environmental impact,” said El-Halwagi.

While treatment of wastewater is currently used, it is often prohibitively expensive and rarely used. In addition, the characteristics of the wastewater vary tremendously from one natural gas well to another. However, according to Dr. Joseph Sang-II Kwon, assistant professor in the chemical engineering department and co-PI on the project, the variable nature of each well presents a unique opportunity to utilize modular systems. “The modular nature of the proposed systems will take care of well-to-well variability such as geological conditions, regional regulations, proximity and capacity of treatment facilities, etc.,” Kwon said.

First, the team will examine and model the dynamic characteristics of the wastewater, and develop computer-aided tools to streamline the modeling process. Once the wastewater is characterized, the team will assess all of the conventional wastewater treatment options – pretreating the water, reverse osmosis, flotation, among others – and carry out experimental testing and prototyping with novel modular technologies – membrane distillation, counter-flow RO systems, novel ionic liquids with a polymeric membrane contactor, and electro-magnetic fields. This experimentation and testing will determine the most effective approach to treating the different characteristics of wastewater from well to well. The environmental impact of different approaches will be considered.

According to Dr. Debalina Sengupta, associate director of the GFRC, the life cycle of the options is critical for sustainability of the chosen options. “When technologies are considered, we seldom are able to take account of all the sustainability aspects that make it truly feasible. The DIAMOND project will consider the true sustainability of the technology options, and will provide the platform for predicting and testing future options.”

The DOE grant is being administered through the Rapid Advancement in Process Intensification Deployment (RAPID) Institute, led by the American Institute of Chemical Engineers. The Texas A&M Energy Institute is leading the modeling and simulation efforts for the institute.